In the spring of 2018 my colleague and builder partner heard Tedd Benson speak at a Maine Indoor Air Quality conference. During the presentation he mentioned a new division of his company called Tektoniks. They were attempting to use their factory to panelize projects by Architects and Builders who were not part of their in-house Bensonwood or Unity Homes team. In April a press release introduced this new division to the public and we jumped at the opportunity to try panelization with their team. We have been playing the panelization game on a much smaller scale with a great deal of success. But the idea of having the insulation, windows, doors, rainscreen, strapping and a completely air sealed envelope delivered to the site and erected in 4-10 days was a huge jump up from our previous version of panelization. Thus far we have found that there is a disconnect between panelization and modular where architects, builders, and even homeowners don’t understand the possibilities and we hope to be on the front edge of the curb showing custom designs, with panelization that bridge the gap between spending 9-12 months swinging a hammer and the ability to provide truly high performance homes.

There were so many questions and it took from the April discussion until January 2019 for us to get everything together and finally see this first project with Tektoniks go up. We originally had the house all planed out as a double wall construction, site built, zero energy home. We ended up re-working our wall systems with templates directly from Bensonwood so they could panelize the house. We were able to streamline the process since our office uses Revit, the same software they start out with before translating that into the program that actually builds the panels. It also gave a second (and really 4-5 extra) set of eyes on the project to catch discrepancies or things that were missed. We talked windows, walls, and opening locations and then were able to provide their team with a paired down model that they could then use to produce the structure and wall panels. Sharing the model back and forth between our teams was easy, although it took a couple of rounds before everyone was clear on what was needed and what was excess information (think things that clients want to see, but aren’t all that useful for panelization). Once the model was approved, they produced a foundation plan for coordination with the design and panels. It didn’t help that this was a challenging site on the side of a hill with walk out basements, slabs + frost walls, ledge and a 1000 foot driveway. It should only get easier from here, but none of that deterred the team in making this happen. It’s a new venture for them, and it was new for us being one of the first off the assembly line. Over time I think everyone will work to iron out the kinks. One of the things I loved best about their company is their open minded discussions on how could we do this better. It was a discovery process finding out what we don’t know, what we think will work, what they don’t know we don’t know and so on. And then they built our walls in the factory and we got to go on the tour!

If you happened to miss it, one of my fellow architects/colleagues, Bob over at Bluetime Collaborative, joined in on our tour of the Tektoniks/Unity facility and wrote his take on the future of panelaziation. Check out his amazing work and his thoughts on panelization here: Notes from a tour of the Unity/Tektoniks factory

Big thank you to the man himself, Tedd Benson, who showed up to meet the client on the factory tour and took time out of his busy schedule to see the project going up in the field. But let’s talk about the factory, the technology, Jay, Tommy, and the rest of the team.

Every morning for every project on the board, the factory team gets together and discusses QDIP – Quality, Delivery, Inventory, Productivity. They discuss what is going well, what could be improved on, where the project is at, and they are open to all feedback on how to do it better, faster, more cost effectively. That, to me, resounded in a very progressive factory. You can feel the atmosphere is different here as well. You proceed on to the extremely precise cutting machine. 1/32” precision. But it doesn’t just cut 2x4 lumber to length. No it cuts, stamps, draws lines for alignment of attached members, grooves for fly rafters, holes, and a series of other attachements that make things easy to assemble in the field, cutting down on error, but also on challenging geometries that are always complicated to erect on site. You proceed along the factory to wall and roof building panel sections. It’s not just the machines that auto nail pieces together based on the pre-cut lumber and the markings on the panels. Or the fact that pneumatic lifts eliminate age or gender from ability to work in the factory. But the careful placement of carts in each section of the factory that use the same nails, tapes, adhesives, and gaskets to make sure that every panel is sealed, taped, and assembled with the minimum amount of shuffling, searching or distraction. But beyond that, you’ll roll up to the section where a roof panel is being dense packed and you’ll run into your site supervisor dense packing the panel. They aren’t away from home 24/7 installing panels, but they aren’t in the factory 24/7 either. And after a certain number of years (4 I think) they can become owners where they are gifted with a toilet brush. Because no matter your position, no one is above or below any job.

Being the architect and the energy professional for this project, I was keenly interested in all the details. How do you keep the cellulose from settling on over the road transport (increase density). How will the windows be installed (center of insulation level, center of wall), how will they be flashed, will the flashing adhere to the Styco? (new product to me – wax impregnated wood fiber board sheathing with an R-5 rating). How will the panels be connected to our foundation walls? How do they get put together on site – gaskets, interlocking sheathing, etc. Some of these things I already had answers to from our computer model and putting their panels into our design. I love the detail that the floor system sits inside the insulated panel getting rid of those complicated details at band joists.

Then the real coordination happens. How do you get 2 trucks a day to back down a 1000 foot driveway to a tight site filled with vehicles and use a crane to lift the vertical panels off the truck? Very carefully, lots of shuffling, and pray there is no snow. Progress was slow the first week because temperatures were in the single digits or below zero with the wind whipping off the lake. But we lucked out the 2ndweek with 40 degree temps and some sunny weather. The 4-6 person crew led by the team member from Bensonwood worked slowly and methodically through the first layer and attaching to the foundation to make sure every layer after that clicked together as seamlessly as possible. There is someone stapling up gaskets, someone giving hand signals to the crane operator, people straping and unstrapping panels. The first few days on site are adjusting, coordinating, and making a plan and this crew worked together well. Our lead carpenter has done commercial, residential frame to finish, and other panelization projects. It’s interesting to hear the talk and discussion around panelization and how this will change the landscape of building. For us, it blows the doors wide open. We can do a winter build and be in an air and weather tight structure in a matter of days. Our female team members can set walls and signal the crane, our framers can erect interior walls and crank through projects faster and more efficiently. No longer do you have to be the site super who swung a hammer for 10 years, now a new skill set has emerged, and better buildings are being built because of it.

The next goal will be for the factory to provide more and more value arriving to the site. If a whole wall can be panelized it can come with wiring, sheetrock and exterior siding. Every extra value provided in the factory will drive the cost down for the consumer and improve the timeline to build a home. I think this new branch of their business might address future issues of poorly performing homes. With little to no modification to my original design, we were able to panelize the walls and construct the exterior shell of this home in a very streamlined manor. That allows different aesthetic styles to come out of factory aside from their Unity Homes and not venturing into the very custom Bensonwood timer frames. Because we have been building panelized construction for a few years, we maybe inherently had wall heights and thicknesses that would work with their system. We also did not have double height spaces or other challenging configurations that would have to be considered to see if it would work within the available panelization. This idea that a more streamlined style of building exists is fascinating and we are thrilled to be part of the first projects to roll off the line.

I won't say it was simple and easy. No new technique ever is, either for the factory or for us. We had a challenging site and a design that was not a box. We had a system that doesn't just click and lock together, so the team had to spend a considerable amount of time making sure the first layer went together well so that all the other pieces above would fit correctly. It was definitely a puzzle. We didn't know what we wouldn't know. No construction project is ever easy, but pushing the boundaries of what is possible fascinates me. I learn something new every time. And I'll be the first to admit, I often learn things the hard way. I love this female led team that I have created. I love the fact that panels can build custom things. And I love to learn more about how to incorporate efficiency into every aspect of the build, even if it wasn't efficient the first way you tried it. Stay tuned for more on this zero energy home, building with panels, the future of sustainable communities and the crazy team at Live Solar Maine.

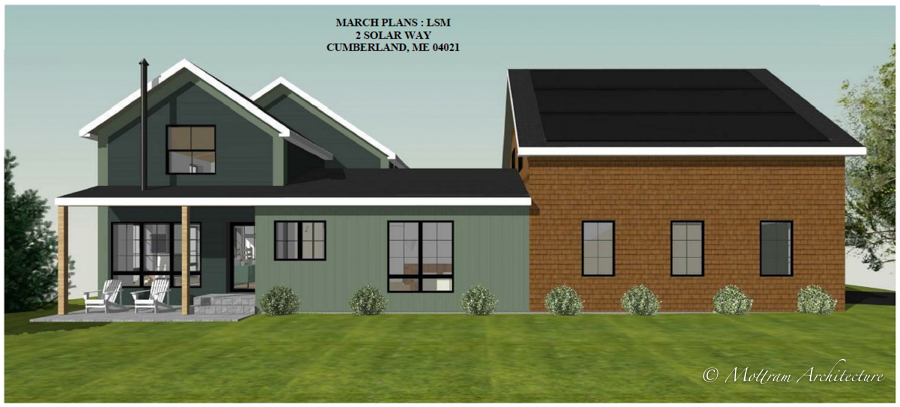

We started with a framer that builds the walls in a shop, delivers them to the site, and 3 days later we have a shell. Framing them in the shop cuts down on time, often taking a 9-12 month build down to 6 months. The quality control and material control can cut waste and job site debris down by almost 25%. And when you're building indoors, weather delays aren't an issue. So while the site is being prepped, framing is happening at the same time. But our framer, he's busy. I wish we had 2 or 3 more to help with construction right now.But how are they different? Why is this different than SIPS panels or modular construction? These are prototypes of zero energy homes. We spend hours in design development working out the systems to cut down on thermal bridging, orient the home the right direction, and provide really great spaces. We are very strict about the materials we use cutting out as much foams, plastics, and formaldehyde products. They are custom homes where we eliminate as much square footage as possible while still spending the time to make spacious areas and a spot for everything. More square footage isn't better, it's just more. In a world where we are seeing people going back to their roots, wanting less, spending more time outside of the home or in a community, this seems like the right answer. Minimizing the impact of building, the buildings impact on environment, and most importantly celebrating it's impact on the occupants. Our health and welfare can be directly linked to where we live.So why aren't we building better? Well the answer is, here at Mottram Architecture, we are.Stay tuned for updates on how the next Live Solar Maine house is going:

We started with a framer that builds the walls in a shop, delivers them to the site, and 3 days later we have a shell. Framing them in the shop cuts down on time, often taking a 9-12 month build down to 6 months. The quality control and material control can cut waste and job site debris down by almost 25%. And when you're building indoors, weather delays aren't an issue. So while the site is being prepped, framing is happening at the same time. But our framer, he's busy. I wish we had 2 or 3 more to help with construction right now.But how are they different? Why is this different than SIPS panels or modular construction? These are prototypes of zero energy homes. We spend hours in design development working out the systems to cut down on thermal bridging, orient the home the right direction, and provide really great spaces. We are very strict about the materials we use cutting out as much foams, plastics, and formaldehyde products. They are custom homes where we eliminate as much square footage as possible while still spending the time to make spacious areas and a spot for everything. More square footage isn't better, it's just more. In a world where we are seeing people going back to their roots, wanting less, spending more time outside of the home or in a community, this seems like the right answer. Minimizing the impact of building, the buildings impact on environment, and most importantly celebrating it's impact on the occupants. Our health and welfare can be directly linked to where we live.So why aren't we building better? Well the answer is, here at Mottram Architecture, we are.Stay tuned for updates on how the next Live Solar Maine house is going:

It takes a little bit longer to build super insulated structure. It takes a little bit more thought to put it all together. But winter days spent inside a home with no drafts, temperatures above 80, and the security of keeping your family warm on these cold cold days makes it well worth it. Not everything in a zero energy house costs money. The simple act of facing the house south can have a huge impact on the way it performs. Spending the time to seal all gaps, cracks, seams, and holes in the envelop is very cheap with an extremely quick return. And air sealing is something pretty much any homeowner can do. The best thing you can do when installing windows is seal around them after they are installed. Instead of stuffing fiberglass next to the windows, use a low expanding spray foam and make sure they are sealed in well. This is where most people see the savings on windows. Put in the best windows you can afford while building, and then seal them. The performance of a window will never equal the performance of an insulated wall. The

It takes a little bit longer to build super insulated structure. It takes a little bit more thought to put it all together. But winter days spent inside a home with no drafts, temperatures above 80, and the security of keeping your family warm on these cold cold days makes it well worth it. Not everything in a zero energy house costs money. The simple act of facing the house south can have a huge impact on the way it performs. Spending the time to seal all gaps, cracks, seams, and holes in the envelop is very cheap with an extremely quick return. And air sealing is something pretty much any homeowner can do. The best thing you can do when installing windows is seal around them after they are installed. Instead of stuffing fiberglass next to the windows, use a low expanding spray foam and make sure they are sealed in well. This is where most people see the savings on windows. Put in the best windows you can afford while building, and then seal them. The performance of a window will never equal the performance of an insulated wall. The  So as you consider building a new home, think about the benefits of building a better home. Take into consideration the costs of building better and the costs of choosing not to on these winter days. It isn't just about the money, it's comfort, durability, and the safety of your family.

So as you consider building a new home, think about the benefits of building a better home. Take into consideration the costs of building better and the costs of choosing not to on these winter days. It isn't just about the money, it's comfort, durability, and the safety of your family. Wishing you all happiness in 2018 and we hope you are enjoying your coffee inside your warm snow globe as the blizzard snow and wind whips around outside.

Wishing you all happiness in 2018 and we hope you are enjoying your coffee inside your warm snow globe as the blizzard snow and wind whips around outside.

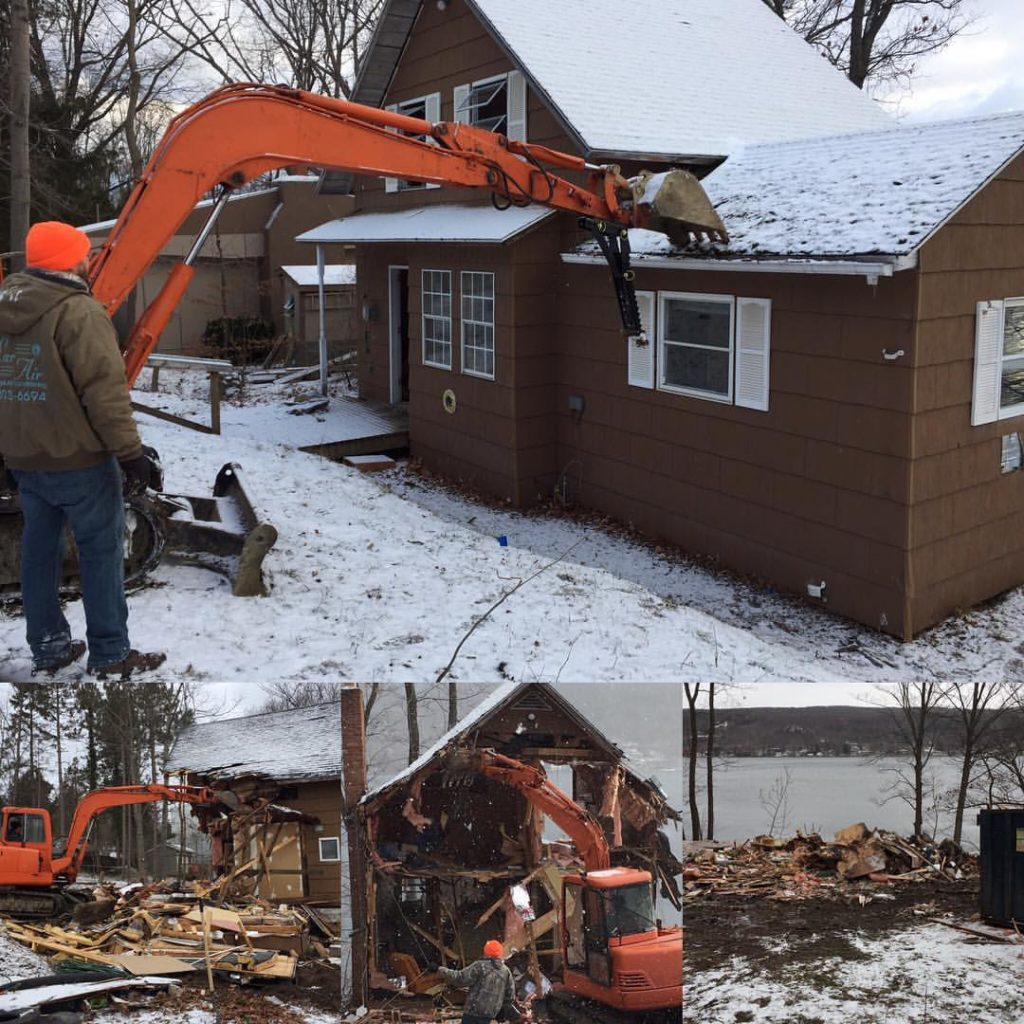

Demolition day! There was an existing structure on the property that had to come down before construction could start.

Demolition day! There was an existing structure on the property that had to come down before construction could start. But look at that view! Beautiful Keuka Lake, Jerusalem NY

But look at that view! Beautiful Keuka Lake, Jerusalem NY Then the digging can begin. This home sits up on the hillside above the lake. So it will have a walk out basement and the first floor will be just below street level.

Then the digging can begin. This home sits up on the hillside above the lake. So it will have a walk out basement and the first floor will be just below street level. Foundation going in

Foundation going in ICF's going up. In energy efficient building, we often talk about how critical it is to get the foundation right! So we have ICF block foundation on the two below grade sections with framed walls on the interior of the basement and 11 1/4" thick double framed walls on the two walk out sides of this house for an R-40 insulation value.

ICF's going up. In energy efficient building, we often talk about how critical it is to get the foundation right! So we have ICF block foundation on the two below grade sections with framed walls on the interior of the basement and 11 1/4" thick double framed walls on the two walk out sides of this house for an R-40 insulation value. Pouring concrete in the ICF's

Pouring concrete in the ICF's Couldn't help but share, sometimes its silly things like this on the job site that keep you motivated to build in the middle of February! There goes the derelict boat, into the dumpster.

Couldn't help but share, sometimes its silly things like this on the job site that keep you motivated to build in the middle of February! There goes the derelict boat, into the dumpster. Block frost walls

Block frost walls A little framing going up on the lake side.

A little framing going up on the lake side. Driveway and rough grading coming down to the garage level and walk out side of the lake. It's so important to create the right type of drainage when changing levels, but especially when building on the lake. It's critical to know where your drainage is going.

Driveway and rough grading coming down to the garage level and walk out side of the lake. It's so important to create the right type of drainage when changing levels, but especially when building on the lake. It's critical to know where your drainage is going. And speaking of drainage, waterproofing is absolutely critical in a Net Zero Homes. We aim for this house to be below 1-2 air changes an hour, so trapped moisture from a bulk moisture source like the ground would be a disaster. It's so important to have a water management strategy and good indoor air quality in a Net Zero Home. More on the ERV in the future!

And speaking of drainage, waterproofing is absolutely critical in a Net Zero Homes. We aim for this house to be below 1-2 air changes an hour, so trapped moisture from a bulk moisture source like the ground would be a disaster. It's so important to have a water management strategy and good indoor air quality in a Net Zero Home. More on the ERV in the future! Steel going in. Sometimes with long spans, you have to move to steel.Stay tuned for more updates on the Keuka Lake Net Zero Home! And check out our friends over at

Steel going in. Sometimes with long spans, you have to move to steel.Stay tuned for more updates on the Keuka Lake Net Zero Home! And check out our friends over at  As we mentioned previously, we partnered with Western Maine Community Action to bring some high efficiency home building to the community. It's a great program, combined with the students at Foster Tech, that is making this happen. Weather in the winter is always unpredictable, but things are coming together slowly and surely. Not only is a great family getting a great home, the Foster Tech students are learning hands on building and energy skills that are invaluable for the future of building and the community we live in!Stay tuned for more updates!

As we mentioned previously, we partnered with Western Maine Community Action to bring some high efficiency home building to the community. It's a great program, combined with the students at Foster Tech, that is making this happen. Weather in the winter is always unpredictable, but things are coming together slowly and surely. Not only is a great family getting a great home, the Foster Tech students are learning hands on building and energy skills that are invaluable for the future of building and the community we live in!Stay tuned for more updates!